Products

-

Low volume production by rapid tooling technology

All projects and manufacturing processes come with their own challenges and guidelines to be successful. There are a number of things you can do to reduce the cost and lead time by using rapid prototyping technology.

-

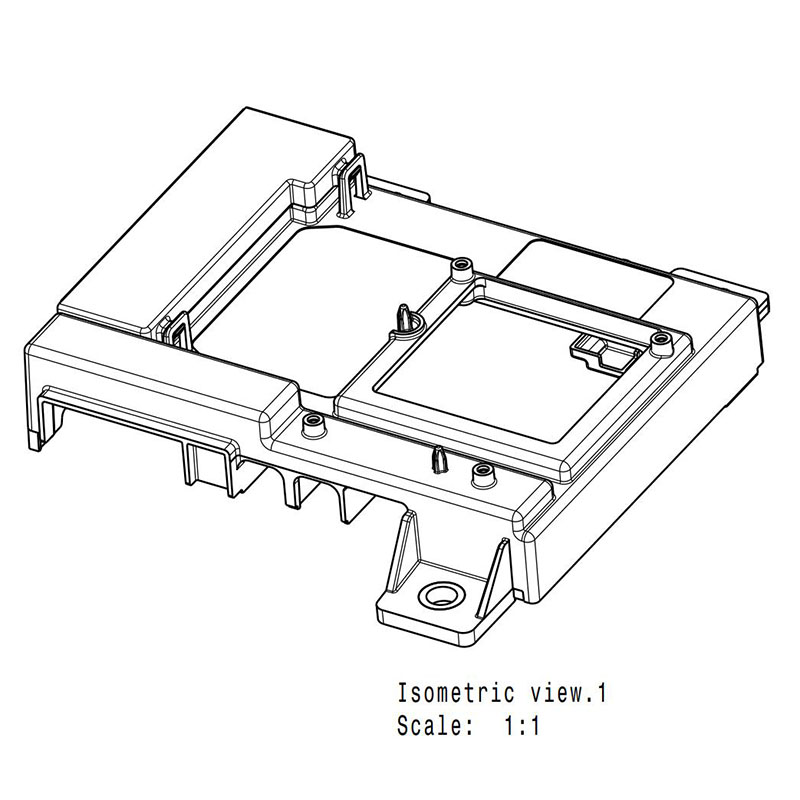

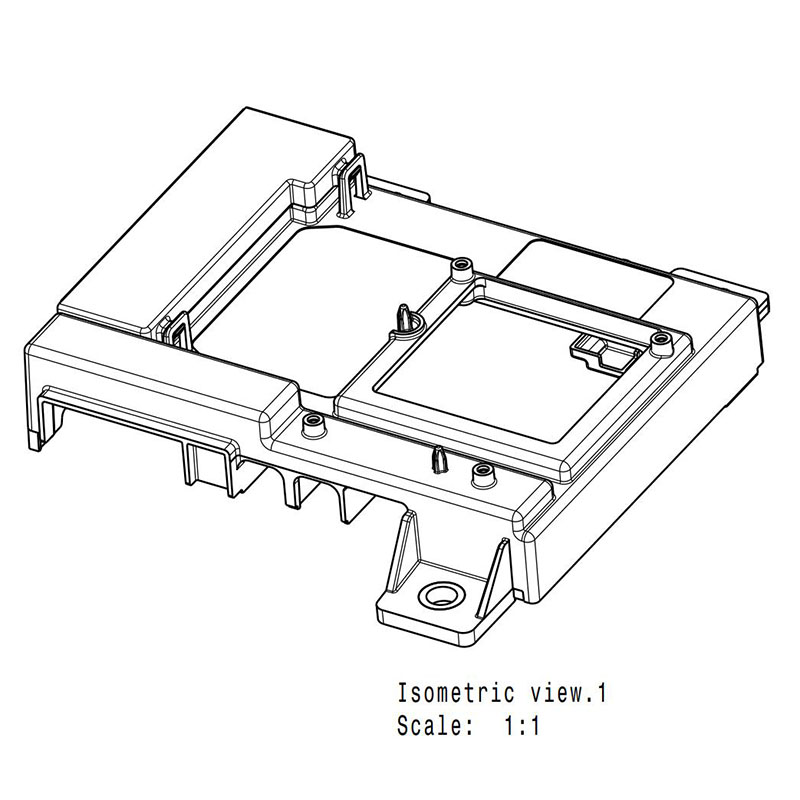

Fast delivery in 3 weeks rapid tooling case

This injection molding project was about paying extra attention during fabrication processes and quality control. Actually, many interior parts are needn’t to be perfect because they are never seen. This part was also never seen but perfection was required for desired functionality.

-

Build prototyping parts without limitation of geometry by 3D Printing

Additive manufacturing or 3D printing is the coming technology of manufacturing. It is opening up a world of 3D prototyping and low-volume rapid manufacturing possibilities. Colead have been providing varieties 3D printing solutions for over 10 years. Rapid prototyping via SLA and SLS paired with our rich experiences enable us to deliver parts with high precision and high-quality every time.

-

Aerospace industry AL7075 CNC maching case

One of customers- Gophyit engines need a large number of customized mechanical components. There are relatively simple components such as brackets, as well as very complex components such as shaft clutches. The clutch of the latest version is composed of 16 different parts, which need different materials, such as Aluminum, stainless steel, POM (Delin), etc.

-

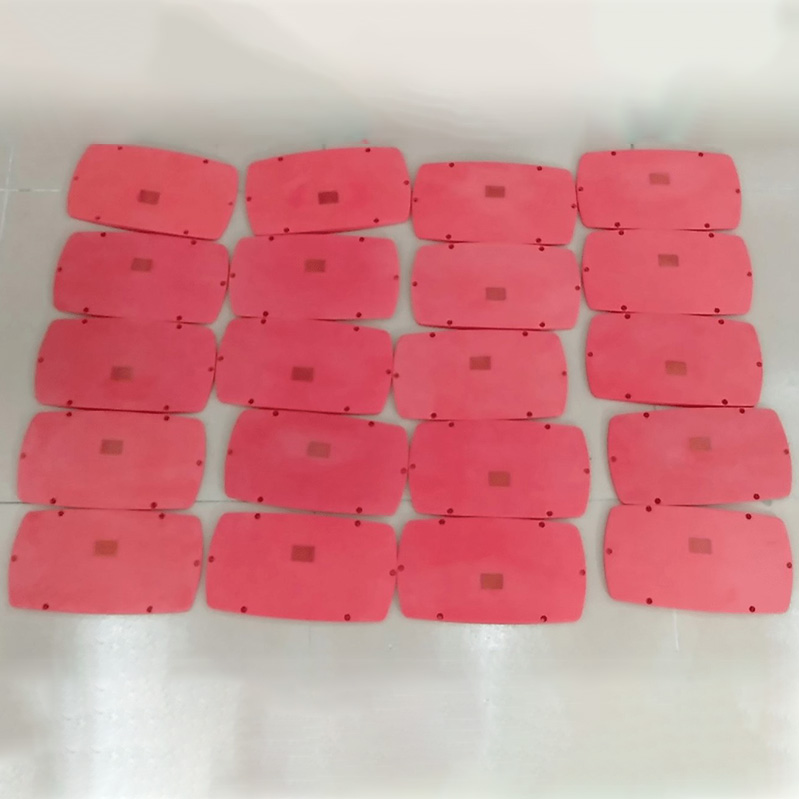

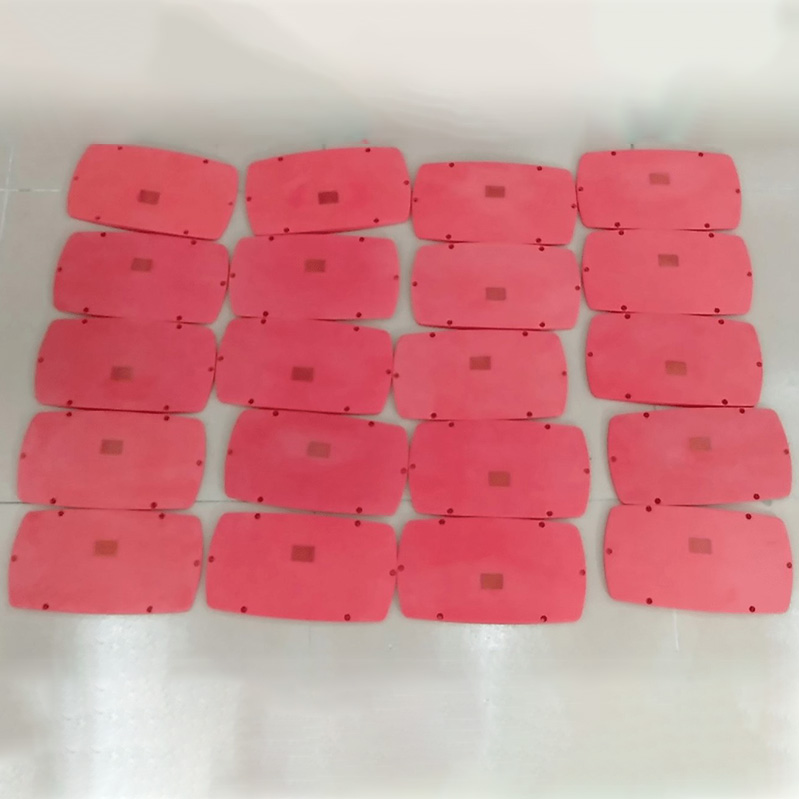

Small batch plastic production urethane casting case

Urethane casting is a great solution for production quality parts without the cost or lead time required for production tooling.

-

Highly flexible rapid low volume manufacturing solutions-CNC Machining

CNC refers to cutting material with a computer numerical control machine. The CNC machining process interprets your 3D CAD model and translates data to CNC machines. The main benefit of the process is that CNC will produce parts that can replace the additive manufactured prototypes with true production grade materials.

-

Most common way to produce large volume production

Injection molding is a manufacturing process for producing parts by injecting melted material into a tooling. Injection tooling can be performed with a host of materials mainly including metals, glasses, elastomers, and most commonly thermoplastic resin and thermosetting polymers. Material for the part is fed into a heated barrel, mixed and injected into a cavity, where it cools and hardens to the configuration of the cavity. Once a product is designed, tooling will be made from metal. Injection molding is widely used for manufacturing a variety of parts, from the small components to big body panels of vehicles.

-

Sheet metal operations from prototype to high volume production

Colead offers a variety of capabilities in sheet metal such as bending, shearing, staking and stamping. Common operations for sheet metal parts include drilling, tapping, counterboring and countersinking. Our sheet metal parts are produced using laser cutting, water jet or chemical etching processes to form blanks from sheet metal stock. Blanks are then bent to shape using press brakes or quick custom tooling to form the final geometry.

-

Low volume plastic production for pre-run by Urethane Casting

Urethane casting is a very nice solution for production quality parts without the cost or lead time required for production tooling. With our in-house urethane casting capacities, at colead we can cast parts as small and big.

-

Small batch Al6061 sheet metal case

Colead offers a variety of capabilities in sheet metal such as bending, shearing, staking and stamping. Common operations for sheet metal parts include drilling, tapping, counterboring and countersinking. Our sheet metal parts are produced using laser cutting, water jet or chemical etching processes to form blanks from sheet metal stock. Blanks are then bent to shape using press brakes or quick custom tooling to form the final geometry.