factory Outlets for Low Volume Injection Molding - Most common way to produce large volume production – Colead

factory Outlets for Low Volume Injection Molding - Most common way to produce large volume production – Colead Detail:

Description

Currently plastic injection molding is still the most common way to produce large volumes of finished plastic parts for every kind of commercial and industrial use.

Advantages

There are many advantages of injection molding:

● Wide plastic resins to choose from for any application.

● Standard lead time 2-4 weeks for T1 samples.

● Most cost-effective way to make large volumes of parts fast.

● A single tool can last for up to millions of cycles.

● Excellent surface quality and dimensional characteristics can be achieved.

● Variety of polishing and texturing capabilities.

● Different plastics can be overmolded for even more design options.

● Injection molding is stable and reliable for predictable result.

● Free Design for Manufacturing Analysis (DFM) with each quote.

Application

Almost for every kind of commercial and industrial use.

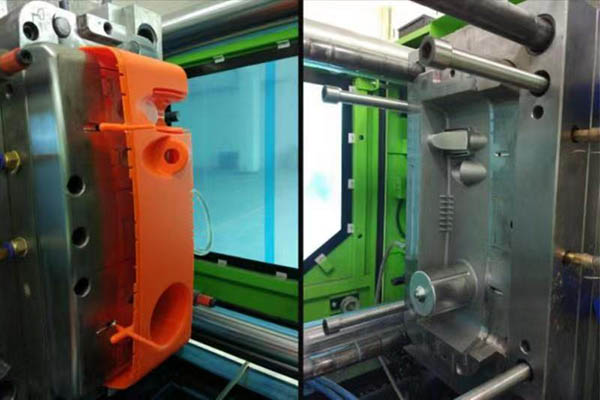

In Colead we are producing high-quality plastic injection molded parts and mold tooling. We supply plastic injection manufacturing for many world first -class companies. We are offering all machining and finishing services to make tooling from a variety of materials, and produce 100 to 200k+ finished parts in all major plastics. Our advanced material verification, inspection and testing will ensure your parts meet and exceed your expectations.

Product detail pictures:

Related Product Guide:

Fast and great quotations, informed advisers to help you choose the correct product that suits all your preferences, a short creation time, responsible top quality control and different services for paying and shipping affairs for factory Outlets for Low Volume Injection Molding - Most common way to produce large volume production – Colead , The product will supply to all over the world, such as: Sri Lanka, Armenia, Madras, Adhering to the principle of "Enterprising and Truth-Seeking, Preciseness and Unity", with technology as the core, our company continues to innovate, dedicated to providing you with the highest cost-effective solutions and meticulous after-sales service. We firmly believe that: we're outstanding as we have been specialized.

We are old friends, the company's product quality has been always very good and this time the price is also very cheap.